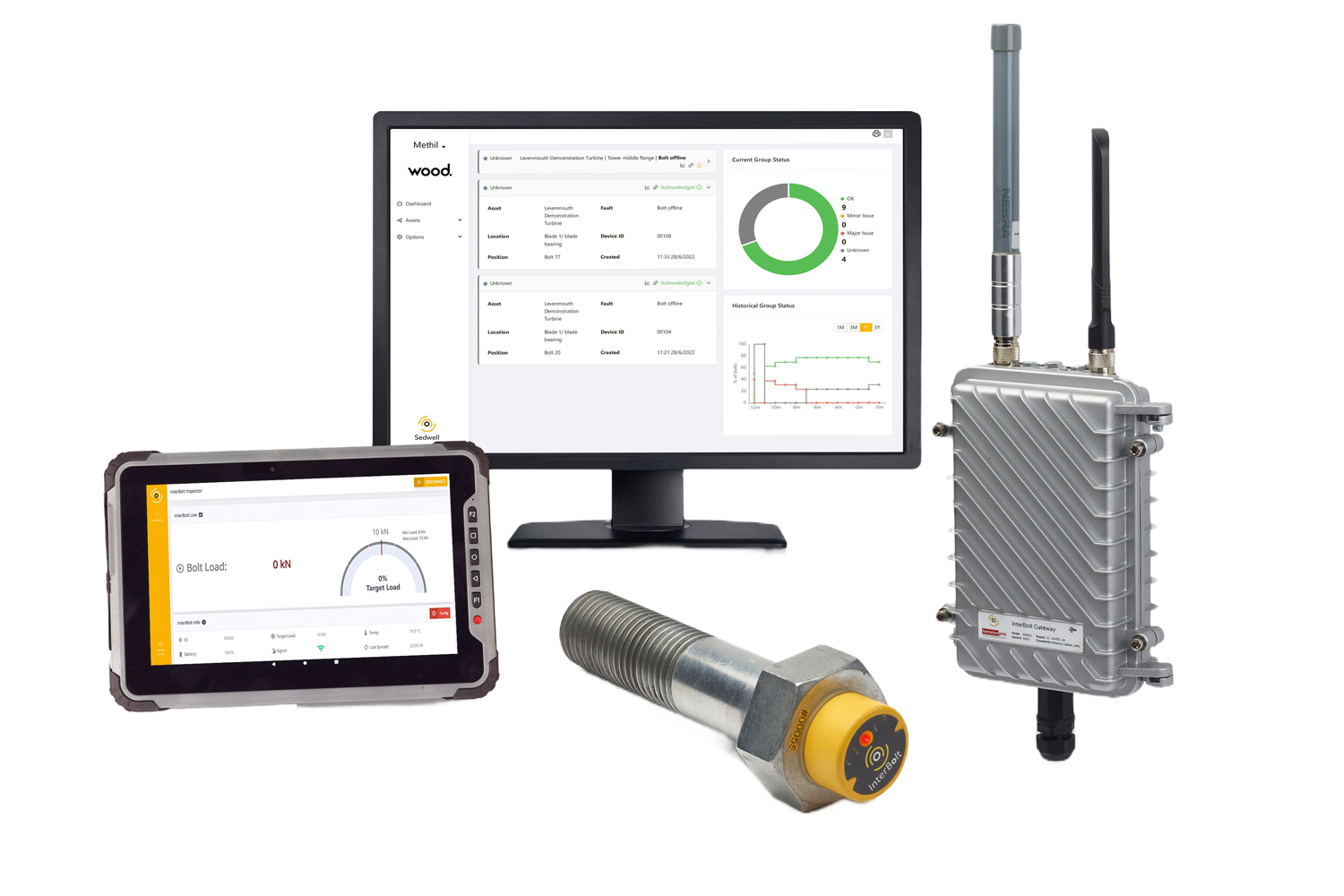

Our InterBolt technology enables you to measure the preload in bolted connections both onsite and remotely. This ensures bolts are tightened accurately onsite, eliminates the need for manual periodic inspection and enables asset failures to be predicted and prevented.

InterBolt technology

InterBolt is a miniature, high accuracy and low-cost bolt load sensor embedded into a bolt or stud. The wireless, battery operated device enables bolt load to be measured both onsite and remotely.

Onsite Monitoring

To quickly verify bolt load, InterBolt provides two methods for monitoring bolt load onsite: inbuilt LED indicators on the InterBolt end cap and through wireless connectivity to the InterBolt Tablet App.

Remote Monitoring

To eliminate the need for bolts to be periodically inspected on site, bolt load measurements from InterBolt can be remotely monitored, in real-time with no technicians on site.